- DUNS: 862413317

- A government recognized star export house.

- +91 932 193 1704

- jolly@jollyclamps.com

Quick Glance at Industries Using HOSE Clamps by Jolly Clamps

November 16, 2023

Jolly Clamps: Beyond the Clamp – How Service-Based Marketing Drives Growth

December 13, 2023Exploring Different Worm Drive Clamp Materials and Their Applications

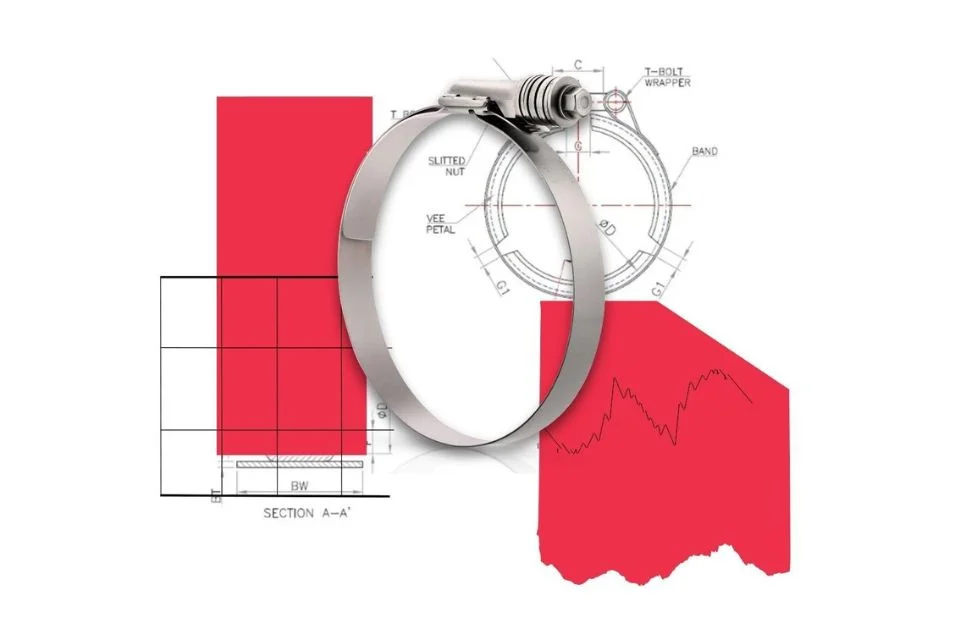

Clamps, the unsung heroes of various industries, play a crucial role in holding components together securely. While often taken for granted, the choice of clamp material can significantly impact their suitability for specific applications. In this exploration, we’ll delve into different types of clamp materials and their suitability across a range of industries

1. Quick Release Worm Drive Clamps – Stainless Steel

Suitability: Quick release worm drive clamps made of stainless steel are exceptionally versatile and find their applications in various sectors.

Applications:

- Electrical: In electrical applications, these clamps are used for cable retaining, ensuring that cables are secured in place.

- Packaging: The packaging industry relies on these clamps to secure packaging materials and equipment.

- Industrial: Quick release worm drive clamps are used in industrial settings for securing components, offering reliability and ease of use.

- Domestic: In domestic applications, they are used for various household purposes, such as home improvement and repairs.

- Hardware: The hardware industry utilizes these clamps for various fastening needs.

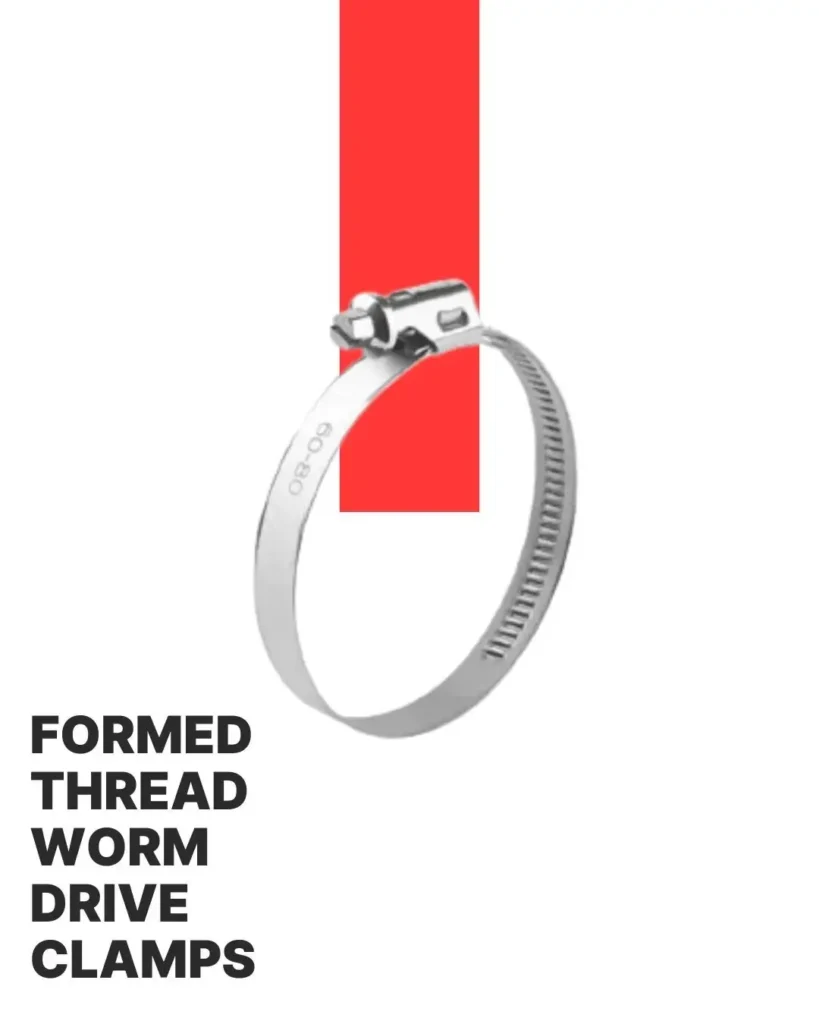

2. Formed Thread Worm Drive Clamps – Stainless Steel

Suitability: Formed thread worm drive clamps are engineered for applications that require high mechanical load-bearing capacity.

Applications:

- Automotive: These clamps are commonly used in the automotive industry, where they secure components subject to high mechanical loads.

- Filter Applications: They find applications in filter systems where the clamps must withstand the pressure and maintain a tight seal.

- Industrial: Formed thread worm drive clamps play a pivotal role in securing heavy machinery and industrial components.

- Domestic: They are used in various domestic applications where reliability and strength are essential.

- Agricultural: The agricultural sector relies on these clamps to secure components in heavy machinery and equipment used in farming.

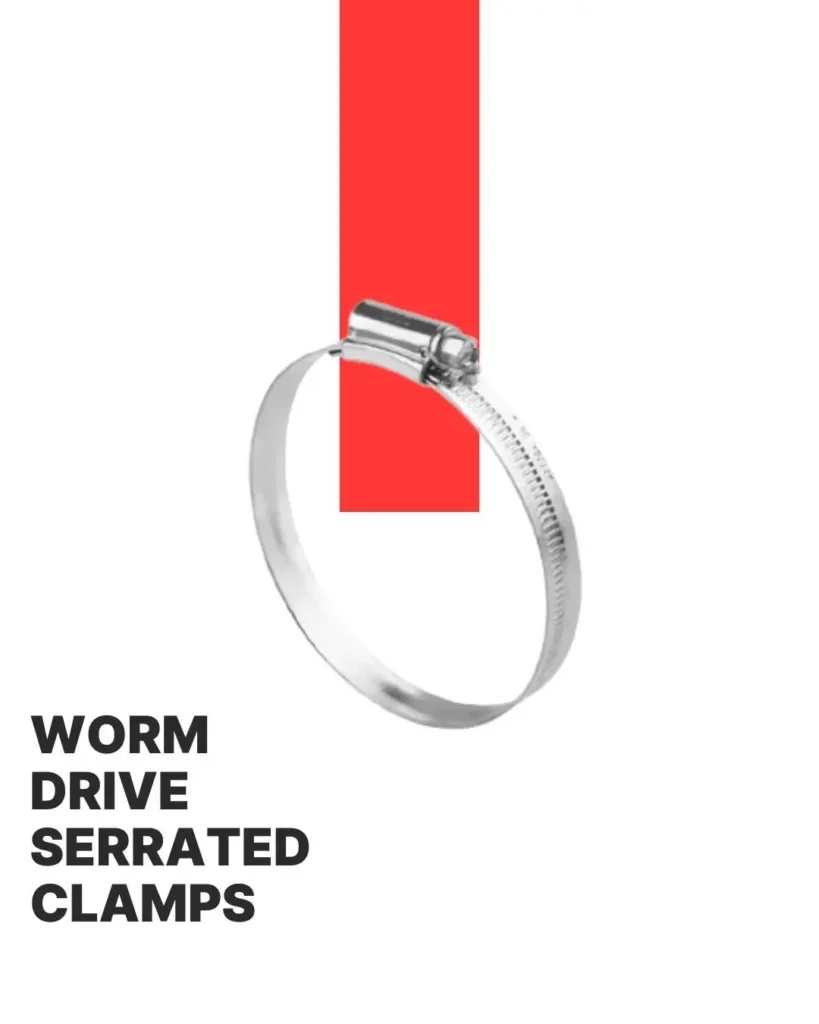

3. Worm Drive Serrated Clamp – Plated Carbon Steel

Suitability: Worm drive serrated clamps are designed for low-pressure and light-duty applications, particularly when securing soft hoses.

Applications:

- Agricultural: These clamps are frequently used in agricultural settings where soft hoses need to be secured in place.

- Light Duty Automotive: In the automotive industry, they find applications in light-duty situations, such as securing non-critical components.

- Industrial: Light-duty industrial applications benefit from these clamps when securing hoses and lightweight components.

- Domestic: Worm drive serrated clamps are suitable for various domestic applications, from DIY projects to plumbing.

- Hardware: The hardware industry often uses these clamps for a range of fastening needs, particularly when lightweight solutions are required.

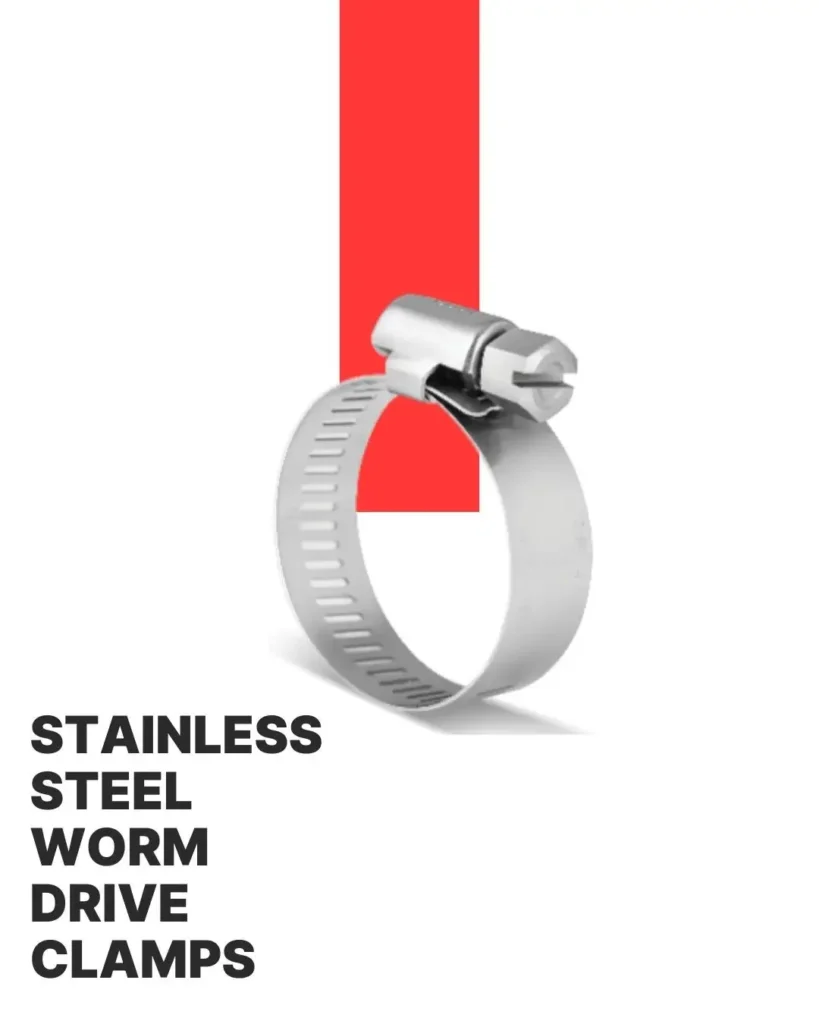

4. Stainless Steel Worm Drive Clamps – Stainless Steel

Suitability: Stainless steel worm drive clamps are designed for medium-duty applications and are suitable for non-throbbing surfaces.

Applications:

- Automotive: In the automotive industry, these clamps secure components with medium-duty requirements.

- Filter Applications: They find applications in filter systems, particularly where moderate clamping force is needed.

- Industrial: Medium-duty industrial applications benefit from the reliability and durability of these clamps.

- Domestic: In domestic settings, they are used for various applications, such as home improvement and repairs.

- Electrical: The electrical industry utilizes these clamps when securing components with medium clamping requirements.

In each of these clamp types, the choice of material is a critical decision that must align with the specific requirements of the application. The versatility of clamp materials ensures that they meet a broad spectrum of needs in industries ranging from automotive and industrial to domestic and hardware.

As technology and materials science continue to advance, new and innovative clamp materials may emerge, further expanding the range of possibilities and suitability for various applications. The world of clamps offers a diverse array of options to meet the diverse needs of industries, making them indispensable components in countless applications. Whether it’s the strength of stainless steel in automotive or the lightweight properties of plated carbon steel in agriculture, selecting the right clamp material ensures secure connections and optimal performance.