Constant torque clamps are indispensable in applications requiring reliable and consistent clamping force. The inclusion of washers in these assemblies enhances their performance by ensuring even load distribution, preventing wear and corrosion, maintaining stability, and facilitating maintenance. Partnering with a trusted Constant torque clamps manufacturer ensures that these critical components meet the highest standards of quality and reliability. By understanding the importance of each component in a clamping assembly, engineers and technicians can ensure the longevity and reliability of their systems.

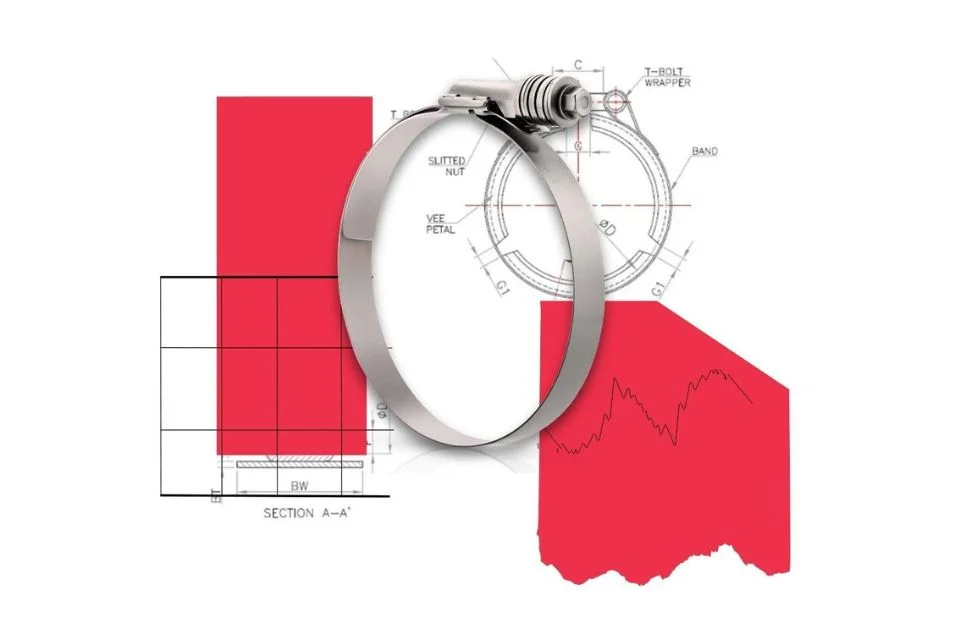

Why Are Washers Imperative To Constant Torque Clamps?

Incorporating quality washers with constant torque clamps not only improves the efficiency of the assembly but also contributes to the overall safety and durability of the application. Whether in automotive, aerospace, or industrial settings, the right combination of clamps and washers is essential for optimal performance.

Washers act as a barrier between the clamp and the material, reducing direct contact and friction. This helps in preventing wear on both the clamp and the material. Additionally, washers can be made from materials that are resistant to corrosion, providing an added layer of protection in harsh environments, thereby extending the lifespan of the components involved.

Constant Torque clamps are crucial for applications needing consistent clamping force. Adding washers enhances performance by distributing load evenly, preventing wear and corrosion, maintaining stability, and facilitating maintenance. Quality washers with constant torque clamps improve efficiency, safety, and durability, making them essential for optimal performance in automotive, aerospace, and industrial settings.