-

jolly@jollyclamps.com

-

Mumbai- 400063, Maharashtra, INDIA.

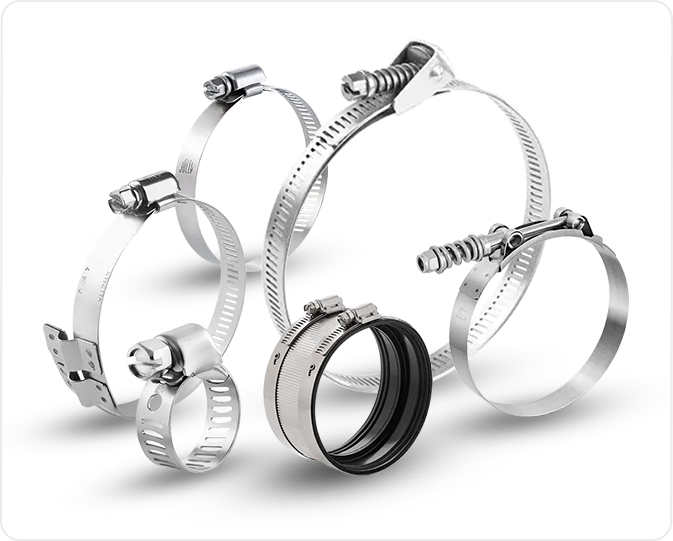

What began over 50 years ago as a focused hose clamp manufacturing unit has evolved into South East Asia’s leading clamping technology partner—trusted by OEMs and industry innovators across the world. At Jolly Clamps, we don’t just make clamps.

Every Jolly product is built on precision, consistency, and global compliance. Our manufacturing systems deliver high-accuracy, application-oriented clamps designed for diverse sectors.

When standard is not enough, we engineer the exceptional. Our R&D and applications engineering teams work closely with OEMs to develop customized Clamps and Couplings.

1

1

We believe in products that last and loop. Our shift to a circular model means reusing materials, minimizing waste, and innovating sustainably.

2

2

We select recyclable steel and minimize hazardous coatings to craft clamps that protect both performance and the planet.

3

3

Our smart practices cut energy use, lower emissions, and reduce waste-less impact, more innovation.

4

4

We're reducing our carbon footprint and exploring clean energy options to power our operations.

Working Employees

Industrial Products

Products Delivered

Years Of Manufacturing Experience

Countries Products Served In

Jolly Clamps Pvt. Ltd. is an industry stalwart providing engineered clamping solution for over 50+ years for diverse applications in sectors such as Industrial, Automotive, incredibly heavy-duty truck clamps, Construction, Agriculture irrigation, farm equipment, Filtration, Food & Beverages, Oil and Gas, Off Road vehicles, Renewable energy.

Read More +

At Jolly Clamps, our state-of-the-art manufacturing facilities are equipped with advanced machinery and automation systems to ensure precision and consistency. We follow stringent quality standards at every stage, from raw material sourcing to final product testing. Our in-house R&D and tool room capabilities enable us to innovate and customize clamps for evolving industry needs.

Your go-to source for industry-leading expertise, technical innovations, and expert guidance on high-performance clamping solutions.

View More +