-

jolly@jollyclamps.com

-

Mumbai- 400063, Maharashtra, INDIA.

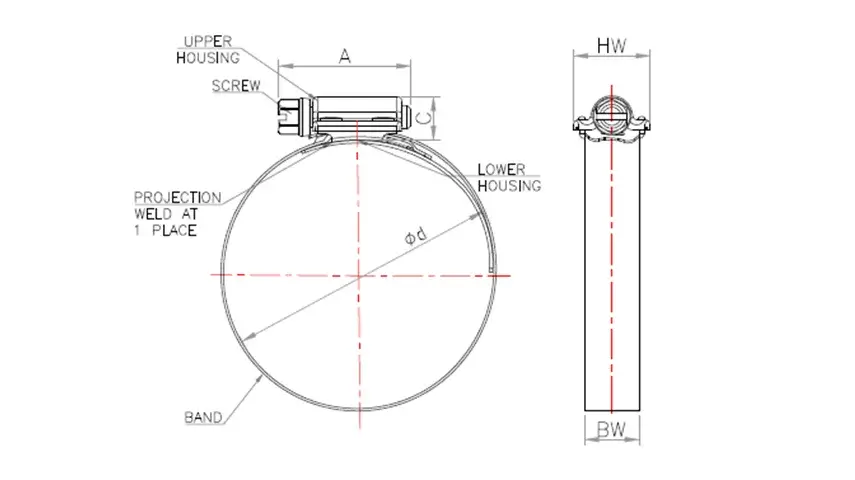

Jolly's Heavy Duty Stainless Steel Worm Drive clamp (SS Worm Gear Clamp) is designed to suit Heavy Duty & High Torque applications. Strong & rigid two piece housing ensures suitability of clamp for Installation torque upto 8.5 Nm & Ultimate torque upto 11.5 Nm. Its durable two-piece housing ensures maximum strength, making it ideal for demanding industries such as automotive, marine, and oil & gas. Available in a range of sizes and material grades, this clamp is engineered to meet global standards.

Also known as Heavy Duty Hose Clamp, Hi-Torque Clamp

Jolly Heavy Duty SS Worm Drive Clamps serve in a wide variety of heavy duty industries while meeting industry specified demand & keeping edge over Quality product supplies. Our products commonly used in industries and applications such as:

Holds IATF 16949, ISO 45001, and ISO 14001 certifications, ensuring high standards.

Products meet RoHS standards, demonstrating commitment to environmental responsibility.

Acts as a "one-stop" provider for diverse clamping needs.

Boasts over 5 decades of manufacturing expertise.

Supplies JOLLY brand clamps to over 80% of OEM and Aftermarket in India.

Exports to North and South America, Europe, and Russia.

Specializes in producing customized clamps.

Emphasizes the importance of lowest lead time.

The Jolly Heavy Duty Stainless Steel Worm Drive Clamp is designed for heavy-duty, high-torque applications in industries such as automotive, marine, oil & gas, and engine applications. It is suitable for high-pressure, vibration-resistant, and demanding installations.

The clamp features a strong and rigid two-piece housing that can withstand installation torques of up to 8.5 Nm and ultimate torques of up to 11.5 Nm. This design ensures maximum strength and stability, making it ideal for high-torque applications like automotive and earth-moving equipment.

The clamp operates using the principle of a worm gear action. This means that the gearing action between clean punched perforations and the thread of the hex head screw enables precise tightening and loosening of the clamp on the application.

The liner prevents direct contact between the perforations in the clamp and the hose. This design feature avoids hose biting, which can occur when the clamp is tightened at high installation torque, thus protecting the hose from damage.

The clamp is made with high-quality materials that meet AISI or equivalent global standards. It is available in SS300 grade, SS316 grade (suitable for marine applications), and SS200 grade series. The screw options include SS300 series, SS410 grade, or plated carbon steel with Hexavalent and Trivalent Zinc plating for enhanced durability.

Yes, the Jolly Heavy Duty Worm Drive Clamp is available in SS316 grade, which is highly resistant to corrosion and is specifically suited for marine applications where exposure to saltwater and harsh conditions is a concern.

These clamps are ideal for a variety of high-torque, high-pressure applications, including automotive, engine applications, earth-moving equipment, marine, and oil & gas sectors. Their robust construction makes them versatile across different industries requiring secure and durable hose connections.