-

jolly@jollyclamps.com

-

Mumbai- 400063, Maharashtra, INDIA.

Jolly Clamp is a T-Bolt Clamp manufacturer serving many top companies in a variety of industries with various types of clamps in large quantities. When it comes to providing Engineering solutions, Jolly TB Model Clamps or Floating Bridge T-Bolt Clamps provide highest quality & consistency to keep your connections together & leakproof.

Jolly T-Bolt Clamps serves in a wide variety of industries while meeting industry specified demand & keeping edge over Quality product supplies. Our products commonly used industries and applications such as:

Holds IATF 16949, ISO 45001, and ISO 14001 certifications, ensuring high standards.

Products meet RoHS standards, demonstrating commitment to environmental responsibility.

Acts as a "one-stop" provider for diverse clamping needs.

Boasts over 5 decades of manufacturing expertise.

Supplies JOLLY brand clamps to over 80% of OEM and Aftermarket in India.

Exports to North and South America, Europe, and Russia.

Specializes in producing customized clamps.

Emphasizes the importance of lowest lead time.

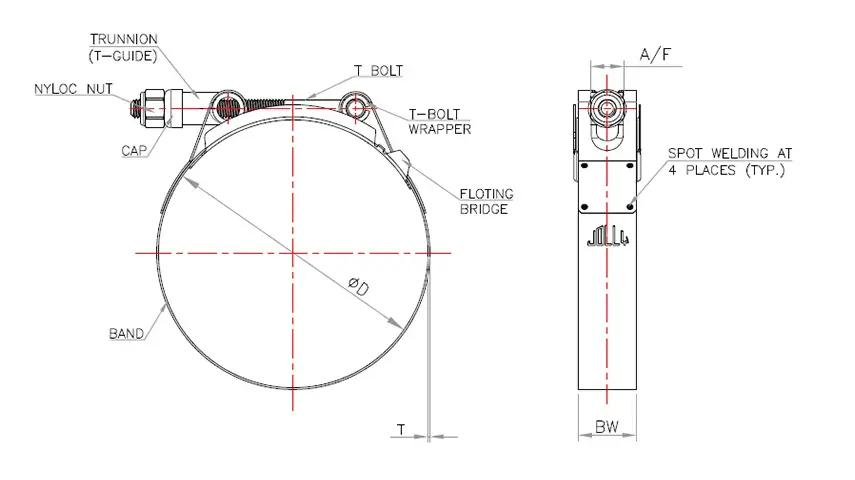

The T-Bolt Clamp with Floating Bridge is designed for high-strength, durable, leak-proof connections. Its floating bridge construction prevents hose puckering and ensures proper sealing, making it suitable for a wide range of industrial and automotive applications.

These clamps are commonly used in: ● Automotive applications ● Filter systems ● Marine applications ● Genset systems ● Agriculture and irrigation systems ● Heavy-duty trucks and earth-moving equipment ● Industrial applications

The floating bridge construction ensures guided tightening, preventing hose deformation or puckering. This results in a consistent, leak-proof seal and protects the hose from potential damage.

Jolly Floating Bridge T-Bolt Clamps are available in: ● SS300 grade stainless steel ● SS316 grade stainless steel (ideal for marine applications) ● SS200 grade stainless steel with plated carbon steel parts All carbon steel components are zinc-plated as per industry and global export standards for enhanced durability and corrosion resistance.

The broad bandwidth and rounded band edges ensure uniform clamping force for 360° sealing, while preventing hose biting or cutting, protecting the integrity of the hose.

The self-locking nut configuration can handle temperatures up to 250°F (121°C), making it suitable for high-temperature environments.

The self-locking nut design prevents the clamp from loosening under heavy vibrations, ensuring a secure and leak-proof connection even in demanding applications such as automotive, marine, and heavy-duty equipment.