-

jolly@jollyclamps.com

-

Mumbai- 400063, Maharashtra, INDIA.

"JOLLY has all required state of the art testing and validation equipment in the Quality Assurance Lab”

Test Offered:-To verify the Material Grade of WIP & finished component

Acceptance Criteria:- As per ASTM Standard

Test Offered:-To verify the Material Grade of WIP & finished component

Acceptance Criteria:- As per ASTM Standard

Tests performed: Compressive strength, Tensile strength, Shear strength.

Specification:- 1) Load Range: 0.5-50 Kg. 2) Minimum thickness of material can be tested : 0.4mm. 3) Hardness Range at 5Kg loading :- 31.08 - 1449 VPN.

Tests performed: To Check the surface Hardness of metal

Specification:- 1) Loading Range: 100Kg, 150 Kg

Range:- 1-100 HRB 2) 1- 100 HRC.

Tests performed: To Check Corrosion Resistance of Surface Coating

Specification:-1) Standard Followed: ASTM B 117 2) PH value – 6.7 3) Flow rate- 30ml in 24 Hrs

Acceptance Criteria:- No corrosion for minimum Assured period of test

Tests performed:- GSM Testing of Packing material

Specification:- 1) Pressure: 0-40 Kg/Sq.cm

Testing Material:- 1) Paper 2) Cardboard.

Tests performed:- To analyse performance of Belleville Washer, Helical Springs at fatigue load

Specification:- 1) Load-500kg 2)Frequency- 68 cycles/Min 3) Displacement- 4-12 mm Variable

Tests performed:- To check the Radioactive inclusion in Incoming material

Specification:- Measurement Range: 0-999.9 mR/hr

Acceptance Criteria:- No Radioactive contamination accepted

Tests performed:- To check the Radioactive inclusion in Incoming material

Specification:- Measurement Range: 0-999.9 mR/hr

Acceptance Criteria:- No Radioactive contamination accepted

Tests performed:- To ensure the performance of clamp under fluctuating hydraulic or air Pressure (fatigue load) after tightening the clamp with installation torque

Specification:- As per IS 4762 standard

Acceptance Criteria:- 3.06-14 Kg/Sqr.cm

Tests performed:- To measure the liner, angular & diametrical dimensions of any component with great accuracy by taking co-ordinates from the machines.

Specification:- 1)Radius, angular, length with MSU 3D PRO software) 2) Magnifying capacity: 10X, 20X, 100X

Tests performed:- At Normal Temperature 1) Axial Load Test 2)Bending Load Test 3)Torsional Load Test

Elevated Temperature (Range- 0-500° C):- 1) Axial Load Test 2) Bending Load Test 3) Torsional Load Test

Test Offered:- Testing of maximum holding capacity of the flanges of V Band clamp at specified torque

Specification:- Max. Hydraulic pressure that can be measured- 280 Kg/ Sqr.cm

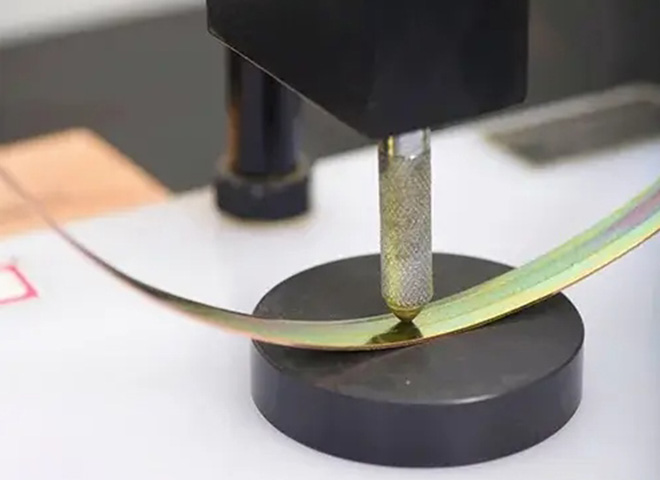

Test Offered:- To measure Plating thickness

Specification:- 1) Range:- 0-30 micron 2) Type of plating :- Zinc coating

Acceptance Criteria:- Measured plating thickness should comply with plating thickness mentioned on customer approved drawing