-

jolly@jollyclamps.com

-

Mumbai- 400063, Maharashtra, INDIA.

No-hub couplings are used to join cast iron pipes having same or different diameter that does not have the traditional Hub and Spigot. They are normally installed with a calibrated torque wrench set at 6.77 Nm (1½” – 10”) or 9.03 Nm (12” & 15”). To install the coupling on cast iron pipes, follow the below procedure;

The manufacturing industry is undergoing rapid changes. Increasingly fast innovation cycles and disruptive forces require fresh minds that understand what our customers need from us. If you dare, there is an opportunity for you.

1) Install the Neoprene sealing sleeve on one end of the pipe or fitting.

2) Place the stainless-steel shield over the other end to be joined.

3) Insert both ends into the sealing sleeve until they fix against the moulded centre stop, inside the sleeve.

4) Centre the shield over the sealing sleeve and tighten as directed below.

Coupling 1½”, 2”, 3”, 4” sizes.

Tighten bands alternately to 6.77 Nm (60 In. lbs) torque

Coupling 5”, 6”, 8”, 10” sizes.

Tighten bands #2 – #3 alternately to 6.77 Nm (60 In. lbs) torque.

Tighten bands #1 and #4 alternately to 6.77 Nm (60 In. lbs) torque

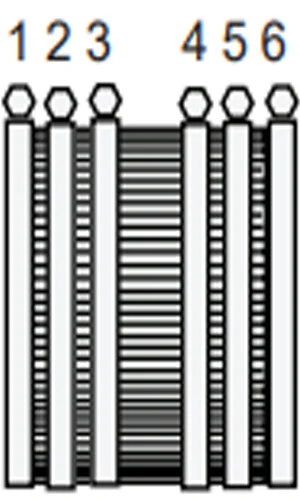

Coupling 12” & 15” sizes.

Tighten bands 3 and 4 alternately to 9.03 Nm (80 In. lbs) torque.

Tighten bands 2 and 5 alternately to 9.03 Nm (80 In. lbs) torque.

Tighten bands 1 and 6 alternately to 9.03 Nm (80 In. lbs) torque.

The shielded coupling is manufactured with a neoprene gasket, stainless steel heavy duty clamps and a corrugated shield. The shielded coupling is encased in a metal structure (corrugated shield) allowing it to be protected from the deflection and constant movement of underground infrastructure layers. Shielded couplings are typically used for underground applications, but can be used above ground. Unshielded couplings are made of similar material and composition as a shielded coupling, but do not include corrugated shield and heavy-duty clamps. While they do create a leak-proof seal, unshielded couplings are not recommended to be used in underground applications where shear forces and heavy earth loads are common.