Introduction

V-band clamps have become the industry standard for joining flanged components in automotive, industrial, and aerospace applications. Their popularity stems from their simplicity, reliability, and superior performance compared to traditional bolted connections. This article explains the mechanical principles behind V-band clamps and why they are the preferred fastening solution.

What Are V-Band Clamps?

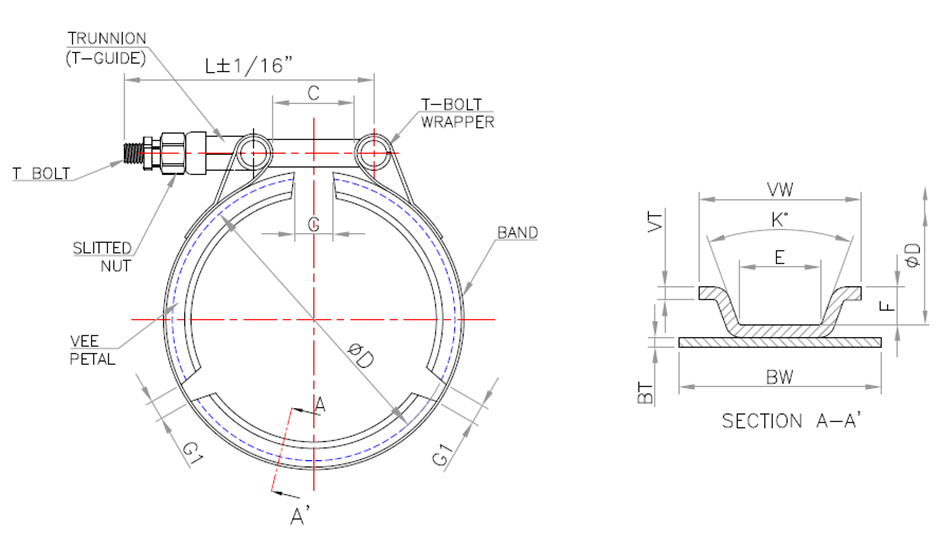

V-band clamps are mechanical fastening devices used to securely join two mating flanged components. They consist of a circular metal band with an internal V-shaped profile retainer and a tightening mechanism, typically a T-bolt or quick-release latch. When tightened, the V-shaped band engages the mating flanges and applies a uniform circumferential clamping force, drawing the components together to form a strong, reliable, and leak-resistant joint.

The Design and Components

A V-band clamp consists of three key components:

Band:

A circular metal band that holds the clamp together and provides the overall clamping structure.

V-Retainer / Insert:

The internal V-shaped profile that engages with the mating flanges and ensures even load distribution around the joint.

Tightening Mechanism (Bolt & Nut):

The fastening system used to tighten the band, applying uniform circumferential force to securely clamp the flanged components.

How V-Band Clamps Work

The Mechanical Process

- The V-band clamp is placed around two mating flanged components.

- The internal V-shaped retainer aligns with the matching flanges.

- When the bolt or latch is tightened, the circular band contracts uniformly.

- The V-profile wedges into the flanges, converting tightening force into radial and axial clamping force.

- This action pulls the flanges together evenly around the full circumference.

- Uniform pressure creates a strong, secure, and leak-resistant joint.

- The clamp maintains joint integrity under vibration, pressure, and thermal expansion.

The Physics Behind the Clamping Force

The clamping force in a V-band clamp is created by the wedge effect of its internal V-shaped profile. When tightened, the applied bolt force is converted into radial and axial forces that pull the mating flanges together evenly. This design ensures uniform load distribution, self-alignment of flanges, and resistance to vibration, resulting in a strong, stable, and leak-resistant joint.

Key Advantages

- Uniform Load Distribution: The continuous line of contact eliminates the stress concentrations common with bolted connections, resulting in better joint integrity.

- Superior Sealing: Uniform pressure creates an effective seal, making them ideal for pressurized applications and preventing leaks.

- Quick Installation and Removal: V-band clamps can be installed or removed without special tools, significantly reducing assembly and disassembly time.

- Vibration Resistance: The distributed clamping force provides excellent resistance to loosening caused by vibration and thermal cycling.

We do not recommend opening the clamp and reclamping for any purpose, as this is not in line with industrial standards. The VTB clamp is designed for one-time use only during assembly.

Common Applications

V-band clamps are widely used across multiple industries:

- Automotive and motorsport exhaust systems

- Turbocharger and intercooler installations

- Custom exhaust fabrication

- Industrial piping and ductwork

- Aerospace applications

- Marine engineering systems

Installation Best Practices

Proper installation ensures optimal performance:

- Inspect the flanges: Ensure mating flanges are clean, undamaged, and properly aligned.

- Position the clamp: Place the V-band clamp evenly so the V-profile fully engages the flanges.

- Engage the fastener: Hand-tighten the bolt or latch to hold the clamp in place.

- Tighten gradually: Tighten in small increments to allow uniform seating.

- Apply final torque: Tighten to the specified torque value for proper clamping force.

- Verify seating: Confirm the clamp is evenly seated around the full circumference.

- Recheck after use: Inspect and re-torque after initial operation or thermal cycling.

Conclusion

V-band clamps represent an elegant and efficient solution for creating reliable, leak-proof connections in demanding applications. Through intelligent use of V-shaped geometry and mechanical advantage, they achieve uniform pressure distribution, superior sealing, and ease of installation. Whether in high-performance automotive systems or critical industrial applications, V-band clamps continue to prove their value as a trusted fastening solution that combines simplicity, reliability, and efficiency.